Fatigue (Aircraft Structure)

Jump to navigation

Jump to search

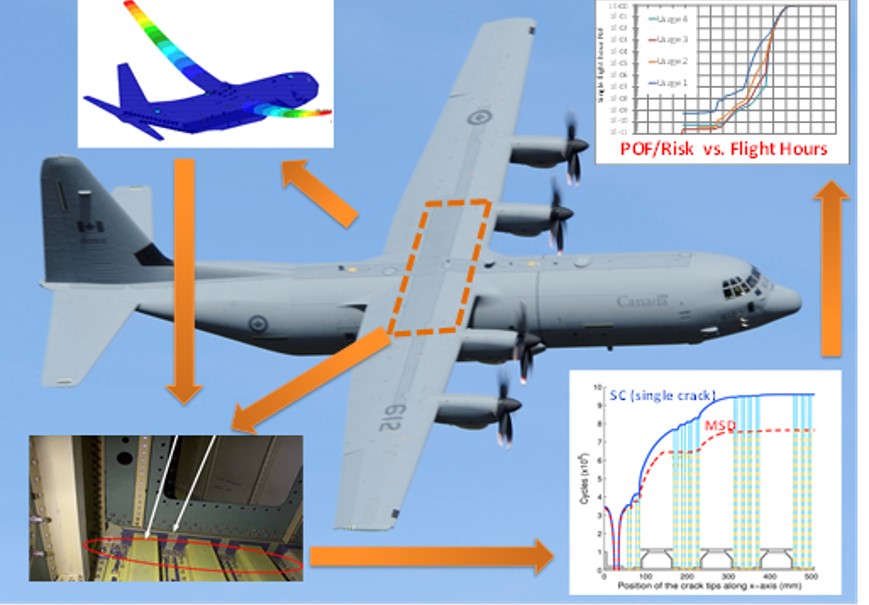

Fatigue in Aircraft Structures refers to the weakening of materials due to repeated stress and strain, leading to crack initiation and propagation, potentially causing structural failure.

Overview

Fatigue is a time-dependent deterioration that affects aircraft structural components due to repetitive cyclic loading during operations. Without detection and mitigation, it can lead to catastrophic failure.

Causes

- Repeated stress from pressurization cycles, G-forces, and turbulence.

- Crack initiation from stress concentrations like fastener holes or surface defects.

- Crack propagation over time with each flight cycle.

- Final failure when the crack reaches a critical size.

Factors Affecting Fatigue

- Material: Aluminum alloys are widely used but fatigue-prone.

- Stress Concentration: Holes, joints, and sharp corners increase risk.

- Loading Conditions: High cyclic loads accelerate fatigue.

- Corrosion: Weakens structures and interacts with fatigue damage.

Crack Growth

- Initiation: Cracks form at stress risers.

- Propagation: Crack length increases with each load cycle.

- Critical Crack Size: Beyond this point, structure can no longer sustain flight loads.

Fail-Safe Design

- Multiple Load Paths: Load redistribution if one path fails.

- Inspectability: Designed for accessible inspection.

- Residual Strength: Withstands damage while remaining functional.

Detection and Prevention

- Regular inspections using non-destructive testing (NDT).

- Adherence to aircraft's fatigue life and Limit of Validity (LOV).

- Repairs and modifications to mitigate damage.

- Maintenance tracking and condition-based actions.

NDT Techniques

- X-ray Radiography

- Computed Radiography (CR)

- Digital Detector Arrays (DDA)

- Ultrasonic Testing

- Liquid Penetrant Testing