Trailing Edge Flaps

Trailing-edge flaps are movable surfaces on an aircraft wing's trailing edge that increase lift and drag, especially during takeoff and landing. They work by increasing the wing's camber, allowing the aircraft to fly at slower speeds while still maintaining lift. Their history includes early plain flaps, followed by more advanced designs like split and slotted flaps, and ultimately, Fowler flaps, which significantly increase wing area.

History of Trailing-Edge Flaps

Plain Flaps (1916): The earliest type, plain flaps hinge downward from the wing's trailing edge, increasing drag and allowing for steeper descents at lower speeds.

Split Flaps: Developed by Orville Wright, split flaps extended from the wing's lower surface, providing more lift than plain flaps but also more drag.

Slotted Flaps: These flaps have a slot between the flap and the wing, allowing airflow from below to pass through and enhance lift, delaying airflow separation.

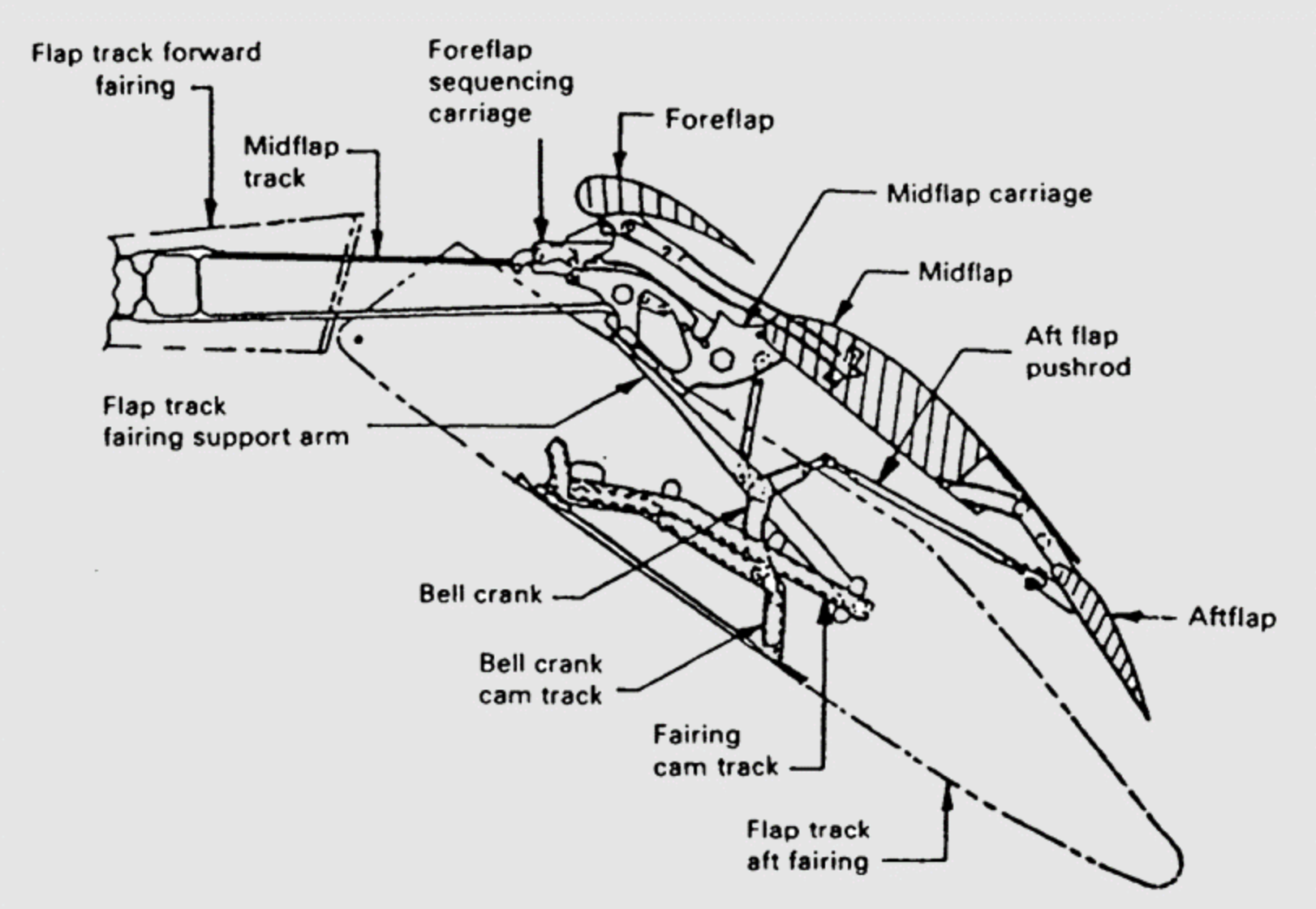

Fowler Flaps: Fowler flaps increase wing area by extending outwards on tracks or rails, often with slots for improved airflow, providing the greatest lift increase.

How Trailing-Edge Flaps Work

1. Increased Lift: By increasing the wing's camber, trailing-edge flaps create more lift at slower speeds, crucial for takeoff and landing.

2. Reduced Stall Speed: Flaps reduce the speed at which the aircraft stalls by increasing the wing's camber and delaying airflow separation.

3. Increased Drag: Flaps also increase drag, which is beneficial for controlled descent during landing.

4. Improved Controllability: Flaps can change the lift distribution on the wing, enhancing the aircraft's handling characteristics.